The environmental impact assessment categories include greenhouse gas emissions,

cumulative energy demand,

human health,

ecosystems,

and resources.

Operational budget impact is modeled based on a comparison of medical waste disposal costs associated with contrast media packaging within a typical radiology department.

Environmental Life Cycle Assessment (LCA)

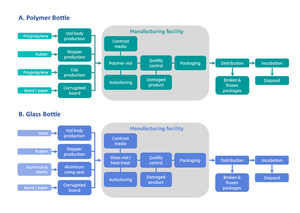

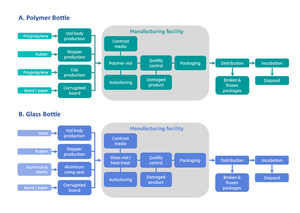

This study looks at the full life cycle of both polymer and glass bottles including supply chain,

product manufacturing,

distribution,

use,

and end-of-life.

The system boundaries for polymer and glass bottles are shown in Fig.

2.

Fig. 2: Product life cycle system boundaries for polymer bottle (A) and glass bottle (B)

Impact assessment methods are used to convert the life cycle inventory data (material,

energy,

and emissions inputs and/or outputs throughout the product life cycle) into a set of environmental impacts.

Since this study focuses on a healthcare product,

human health impacts are of primary importance.

The healthcare industry is also keenly aware of energy and solid waste issues.

To address these perspectives,

this study uses human health midpoint impact categories and ecosystem quality and resources endpoint impact categories from the internationally accepted method ReCiPe (H/A) [3],

along with Cumulative Energy Demand (CED) [4],

which expresses both embodied and process energy associated with a product’s life cycle.

A summary of environmental impact categories used in this study is shown in Table 1.

| Table 1.

Environmental impact categories considered

|

| Impact category |

Unit |

Source method |

| Climate change |

kg CO2eq |

ReCiPe Midpoint (H) v 1.07 [3]

|

| Ozone depletion |

kg CFC-11eq |

| Human toxicity |

kg 1,4-DBeq |

| Photochemical oxidant formation |

kg NMVOC |

| Particulate matter formation |

kg PM10eq |

| Ionizing radiation |

kg U235eq |

| Ecosystem quality |

species.yr |

ReCiPe Endpoint (H) / World ReCiPe (H/A) v 1.07 [3]

|

| Resources |

economic unit |

| Cumulative energy demand |

MJ |

Cumulative energy demand v 1.08 [4] |

The climate change impact category within the ReCiPe (H) Midpoint method includes all greenhouse gases specified in the Kyoto Protocol (carbon dioxide,

methane,

nitrous oxide,

hydrofluorocarbons,

perfluorocarbons,

and sulphur hexafluoride) using global warming potentials from the IPCC 4th Assessment Report with a 100-year time horizon [5].

The primary results presented here focus on the 100 mL bottle size,

but the study also compared several different bottle sizes on a functionally equivalent “per dose” basis – two 50 mL bottles,

one 100 mL bottle,

half of a 200 mL bottle,

and one fifth of a 500 mL bottle.

The study considered a variety of end-of-life disposal options for both bottle types including: (i) municipal waste disposal; (ii) autoclave and landfill; (iii) autoclave and incineration; (iv) pre-shred,

autoclave and incineration; (v) incineration; and (vi) recycling.

Additional sensitivity analyses were performed to assess the effect of different electricity grids (manufacturing geographies),

recycled content in glass bottles,

mode of distribution transport,

different contrast media solutions,

and X-ray vs.

MRI diagnostic applications.

This assessment was conducted according to the ISO 14040-44 standards for comparative LCA [1,2] and was independently reviewed by a third-party critical review panel.

Economic Evaluation

The operational budget scenario was based on a typical 200-bed hospital radiology department in the US that purchases approximately 11 700 bottles of contrast media per year.

For each bottle type (polymer or glass),

an average bottle weight was calculated by measuring the weight per unit of each bottle size and then weight-averaging based on 2013 sales volume percentages for each bottle size (the sales volume bottle size distributions were the same for both polymer and glass bottles).

The cost of medical waste disposal was estimated at $0,17/lb [0,32 EUR/kg] based on published data [6],

and cross-checked with a secondary published source [7].

The more conservative data source [6] was used in the calculations.

Annual cost reduction associated with medical waste disposal was calculated as the annual weight reduction (glass – polymer) x 0,32 EUR/kg.